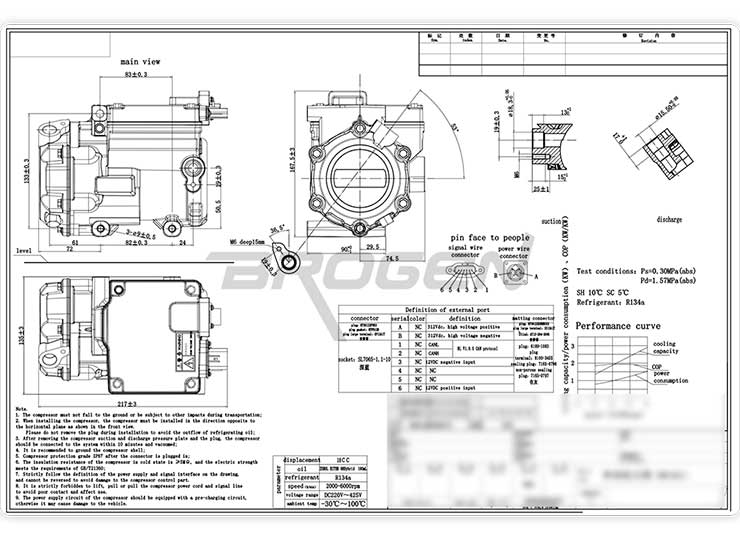

Our collaboration with the Korean light truck manufacturer began with a thorough analysis of the client’s vehicle model. Based on the specifications provided, we recommended appropriate auxiliary systems for their light trucks. This included matching the air conditioner compressor and electric water pump to the vehicle's existing components, as well as integrating a DCDC converter and EHPS system.

September 2021 to January 2023

1.5-2 Tons light Trucks

During the design and development phase, meticulous attention was paid to the customer’s truck frame. We recognized that the installation of the electric water pump necessitated modifications to its bracket to ensure optimal compatibility and performance. This customization was pivotal in maintaining the integrity of the overall vehicle architecture. Additionally, we adapted our products to the client's CAN communication protocol, adjusting the content and communication speed to meet their unique requirements.

During the testing phase, our engineers provided remote support, assisting with software protocol adjustments to ensure seamless integration. By early 2023, the first batch of 50 vehicles was ready for deployment, with plans for further production by the end of 2024.

One of the significant hurdles was the customer's decision to modify their voltage platform midway through the project. Our engineers conducted a comprehensive evaluation and ultimately advised the customer that it would be best to maintain the original voltage platform. This recommendation was crucial in ensuring that the auxiliary systems remained compatible and reliable. Fortunately, the customer heeded our advice, which resulted in continued project momentum without further complications.

In adapting our products to the customer’s requirements, our team had to make significant adjustments to the CAN communication protocols. The necessity to switch to their standard frames posed a challenge, but our talented engineers worked diligently to modify the CAN protocol, significantly contributing to the successful integration of our auxiliary systems within their light truck.

Through our case study with the Korean light truck customer, it is evident that successful project execution hinges on effective communication, technical expertise, and a willingness to adapt to change. By addressing challenges and proactively communicating valuable solutions, we demonstrated our commitment to customer satisfaction and product excellence.

Our experience has equipped us with the insights necessary to tackle similar projects in the future, further enhancing our capabilities within the market. As we continue to innovate and deliver high-quality auxiliary system products—including air conditioner compressors, electric water pumps, EHPS, and DCDC converters—we are poised to meet the unique demands of the automotive industry.

For the latest news please view Brogen’s Linkedin. For more videos please click Brogen’s Youtube.