The power system of electric vehicles relies on battery components and motors, which consume considerable power and generate heat. This heat can raise the battery's temperature during charging and discharging, impacting its internal resistance, voltage SOC, capacity, efficiency, and lifespan. Lithium-ion batteries operate optimally between 15-45°C; lower temperatures can reduce output and range. An effective thermal management system is essential for maintaining battery efficiency and extending its lifespan, which is vital for the performance and economy of electric vehicles.

Lithium-ion batteries operate optimally at 15–45°C (±2°C) according to SAE J2929 standards. Deviations trigger measurable performance losses:

| Condition | Capacity Loss | Cycle Life Reduction |

|---|---|---|

| Continuous 55°C operation | 3.3%/month | 60% decrease @ 800 cycles |

| Sub-zero (-20°C) charging | 40% Li plating | 500-cycle premature failure |

Both excessively hot and cold temperatures have similar impacts on electric vehicle batteries and their health:

● Reduced Charging Capacity: Extreme temperatures increase the force required for the current, which drives lithium ions from one node to another within the battery and may cause damage to the nodes. Energy may leak and fail to be stored. The higher the current, the more likely the battery is to suffer from stress fractures, deplete lithium, and hinder energy flow.

● Decreased Ability to Retain Charge: The length of time a battery can hold a charge also decreases with extreme temperatures. A fully charged electric vehicle left overnight in freezing temperatures might lose 20% of its power.

● Reduced Range: When charging capacity is lowered and the battery struggles to maintain its charge, an electric vehicle will not be able to travel as far on a single charge and will require more frequent charging. Opting for fast charging cycles puts additional stress on the battery.

● Shortened Overall Lifespan: Batteries overburdened by temperature simply cannot last as long. Since replacing the battery in an electric vehicle is one of the most expensive repairs for both consumers and manufacturers, protecting battery life is crucial.

Even when an electric vehicle is not in use (charging), the thermal management system continuously works to monitor or maintain internal temperatures within the optimal range. Although any temperature outside the optimal comfort zone can affect the efficiency of the electric vehicle, the vehicle is equipped with intelligent systems to keep the system within its own comfort zone.

Typically, during discharge, batteries prefer to stay below 45 degrees Celsius, while during fast charging, they prefer temperatures slightly above this, around 55 degrees Celsius. Therefore, temperature management is a balancing act that ensures the battery's performance is fully utilized.

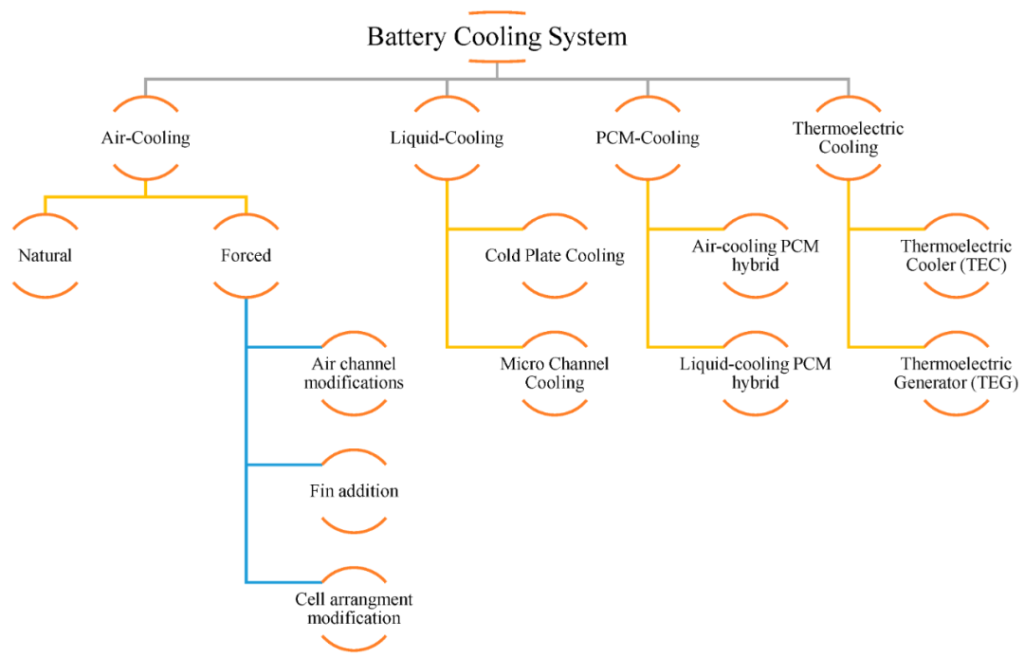

Traditional battery thermal management methods, such as air cooling and liquid cooling, while capable of providing a certain degree of heat dissipation, still face issues like uneven heat dissipation and high energy consumption.

To overcome these shortcomings, researchers have begun to actively explore the application of new thermal management technologies in the field of power batteries. Among these, PCM (Phase Change Material), heat pipes, and thermoelectric cooling technologies stand out due to their unique advantages.

The Battery Thermal Management System (BTMS) is crucial for maintaining the optimal performance and longevity of lithium-ion battery packs. Battery efficiency is highly dependent on temperature, and effective thermal management can address temperature inconsistencies, enhancing battery performance in electric and hybrid vehicles.

For the latest news please view Brogen’s Linkedin. For more videos please click Brogen’s Youtube.